【Product Name】:ZPW25 tablet press of electronic products

The machine used for all kinds of granular materials into a sheet, in addition to wafer can also suppress the shaped pieces of various geometric shapes, double-sided lettering piece. The structure of the double pressure type, there are two sets and two pinch roller feeding device. 25 can be mounted on the wheel to pay active-style punch, you can suppress the revolution 50. When pressed discs, according to the diameter size of the piece, punch rod can be installed dual-flush, three red and four red, it is suitable for mass production. Tableting turntable speed, filling depth, tablet thickness of the material, the height can be adjusted under the hoisting. Random with a separate suction powder box, through the suction pipe and nozzle powder can absorb dust generated during operation of the machine, to avoid clogging dust adhesion and re-use of recyclable materials.

| Die number | 25 pay |

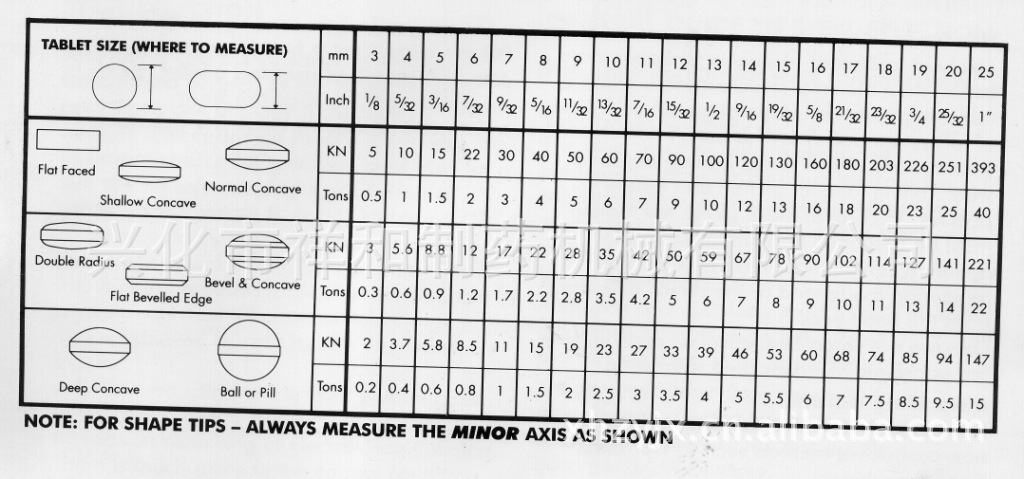

| Maximum tablet pressure | 80 kN |

| Maximum tablet diameter | 20 mm |

| The maximum depth of filling | 15 mm |

| The maximum thickness of the tablets | 9 mm |

| Wheel speed | 6-10 r/min |

| Motor | 3 kilowatts 950 rev/min 380 V/50 Hz |

| Dimensions | 1000×1100×700 mm |

| Machine weight | 1800 kg |

1, the pharmaceutical industry: Herbal tablets, medicine tablet, nutrient tablets, veterinary medicine, etc.

2, the food industry: candy pieces, coffee tablets, lozenges, chocolate beans, seasonings block, etc.

3, the health care industry: buccal tablets, milk tablets, calcium tablets, propolis tablets

4, electronic battery industry: electronic components, such as button batteries

5, the chemical industry: mothballs, aromatic balls, fertilizer tablets, mosquito coils, catalyst, disinfection tablets, powder, etc.

6, metallurgical ceramics industry: Catalyst, grain powder metallurgy, ceramics grain, metal sheets, etc.

The working process of the tableting machine can be divided into the following steps:

A lower punch punch site(its working position upwards) Central die hole extends into the lower end of the die hole, seal the bottom of the hole in the mold;

2, the use of the feeder to the drug filling the die orifice;

3, on the red punch site(its working position down) since the fall of the upper mold die hole hole, and certain travel downstream, the powder into tablets;

4, on the red ascend out of the hole. Undershoot rise to the top of the tablet in the die hole, to complete a tabletting process;

5, rushed down to the next place, ready for the next one to fill.

1. Dose control

There are a variety of tablets of different dosage requirements, high dose adjustment is accomplished by selecting a different diameter of the punch die to achieve. After choosing the size of the die, the tiny dose adjusted by adjusting the depth of the lower punch inserted into the die hole, so as to alter the actual length of the back after the die orifice, a die orifice to regulate

The purpose of the fill volume of the drug. Therefore, on a tablet machine should have adjusted undershoot in the mold of the original location of the hole institutions to meet dose adjustment requirements.

2. Thickness and compaction control pills

Dose is determined according to the pharmacopoeia of prescription and can not be changed. For storage, preservation and disintegration time requirements, tableting pressure on certain dose is required, and it will also affect the actual thickness and appearance of the tablets. Tableting pressure regulation is essential. This is accomplished by adjusting the hole punch in the mold to achieve the amount of downlink. Some tablet tableting machine with a punch not only during downward movement, but may also have a lower punch upward movement, by the upper and lower punch relative movement together to complete the compression process. But more than that to achieve a pressure regulator pressure regulator and control impulse downward adjustment amount by the institution.

[Details show]