【产品名称】:SF不锈钢粉碎机组

SF不锈钢粉碎机组

工作原理

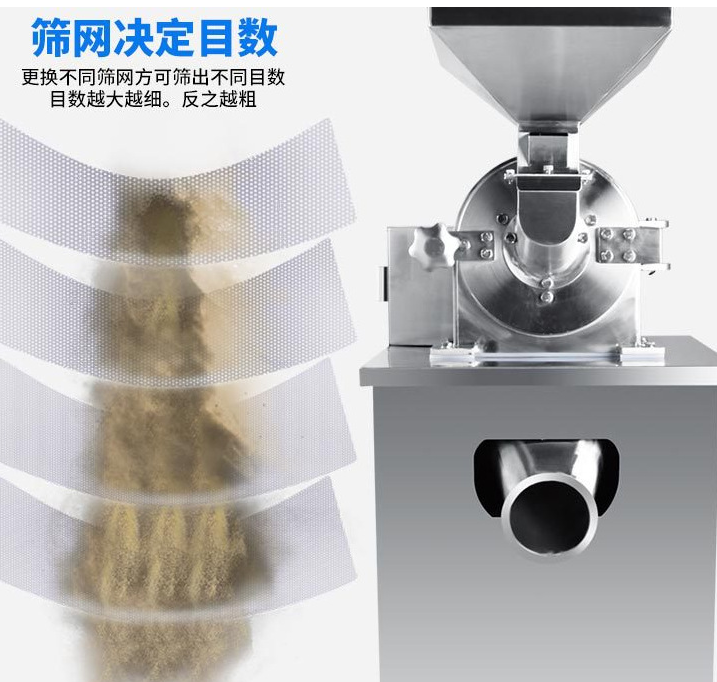

本机采用了风轮式高速旋转刀,定刀进行冲击、剪切研磨,不但粉碎效果好,而且粉碎时机腔内产生了强力的气流,把粉碎室的热量和成品一起从筛网流出,粉碎细度可更换筛网来决定。本机组利用活动齿盘与固定齿盘间的相对运动,使物料经齿盘冲击、摩擦及物料彼此间冲击而获得粉碎。粉碎好的物料4旋转离心力的作用,自动进入捕集袋,粉尘由吸尘箱经布袋过滤回收。

WORKING PRINCIPLE

This machine adopts the wind wheel type high speed rotary knife, knife shock, cutting and grinding, not only has good grinding effect and the crushing time accompanied by strong airflow inside the grinding chamber, the heat and the finished products through the screen out of the crushing fineness screen to decide. The utility model utilizes the relative motion between the movable tooth plate and the fixed tooth plate, so that the material can be crushed by the impact of the gear plate, the friction and the impact of the materials. The utility model is characterized in that the material 4 is broken, and the centrifugal force is automatically applied to the collecting bag.

技术参数 TECHNICAL PARAMETERS

|

型号 Model |

SF-20B |

SF-30B |

SF-40B |

SF-50B |

|

生产能力Production capacity(kg/h) |

5-150 |

20-300 |

60-800 |

100-1400 |

|

主轴转速Spindle rotation speed(r/min) |

5800 |

4500 |

3800 |

3200 |

|

进料粒度Feeding size(mm) |

6 |

10 |

12 |

12 |

|

粉碎细度Crushing fineness(Mesh) |

60-150 |

60-120 |

60-120 |

60-120 |

|

粉碎电机Crushing motor(kg) |

4 |

5.5 |

7.5 |

11 |

|

吸尘电机Dust collection motor(kw) |

0.55 |

0.75 |

1.1 |

3 |

|

外形尺寸Overall size(mm) |

1100×600×1650 |

1200×650×1650 |

1350×700×1700 |

1400×800×1750 |